Vibration monitoring doesn't have to be difficult

Are you looking for an efficient, accurate, and easy-to-install vibration monitor? Look no further than the SWARM Vibration monitor! This advanced technological device is the ultimate solution to control your environment.

SWARM vibration monitor

Effortless construction vibration monitoring

The SWARM Vibration monitor performs high-quality vibration measurements at construction and infrastructure sites. It sends the measurement data wirelessly to the Honeycomb web platform, where you can view it in real-time. If the vibration levels are so high that adjacent structures are at risk of being damaged or residents likely to experience nuisance, you will receive instant alerts.

Innovative MEMS technology

The SWARM Vibration monitor uses MEMS technology. MEMS sensors improve your monitoring experience by saving time, money, and effort while providing the same accurate monitoring data you're used to.

Easy-to-install vibration monitor

The compact (4.29 x 5.12 x 1.77 in or 10.9 x 13 x 4.5 cm) and lightweight (9.17 oz or 260 gr) SWARM is quick and easy to install. You can configure the device remotely via the Honeycomb platform, where you can always view your data from any device.

Hands-free, over-the-air updates

Over-the-air updates enable you to always work with the latest version of the monitoring software without raising a finger.

Try out the SWARM Vibration settings on Honeycomb for free!

Vibration monitor with MEMS technology

MEMS is an abbreviation for 'microelectromechanical systems.' MEMS technology allows for the manufacturing of microscale devices such as sensors. Those miniature silicon chip devices are highly reliable and rapidly responding. MEMS-based sensors are suitable for construction work and nuisance, structural health monitoring, and traffic monitoring. They work particularly well in projects where:

- You want to benefit from remote monitoring.

- Less experienced people install a vibration monitor.

- Real-time insights and remote access are crucial.

Using the MEMS-based SWARM Vibration monitor means a

two-year calibration interval instead of a yearly one, reducing downtime and costs for your projects.

Any questions? Reach out to sales expert Jurjen Cats!

When it comes to understanding our solution and how it perfectly suits your needs, Jurjen Cats is the person you should reach out to.

5 steps to start measuring

Mount the SWARM

Simply mount the SWARM Vibration on a wall using a single screw. No hassle with alignment, just secure it on the wall with the Omnidots logo up.

Power up

Connect the SWARM Vibration to your power source, SWARM Battery, or Solar Panel.

Auto alignment

The SWARM Vibration now conducts auto alignment and starts measuring.

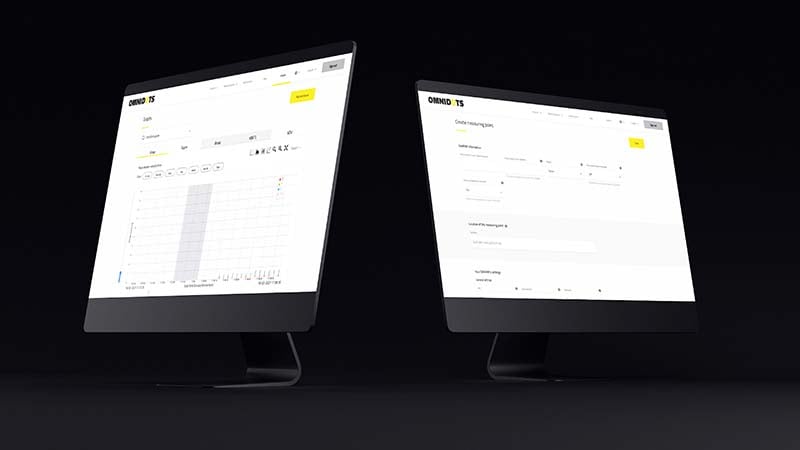

Set up online

Log in to your Honeycomb account. Here you can adjust the measurement settings and select options for alarm notifications.

Go!

You can now view measurement data and generate customized reports, 24/7, anywhere on any device!

What others say about Omnidots

![]()

"If I had used equipment other than the Omnidots sensors in these projects, I probably would have spent much longer processing the data and taking the measurements. In terms of operations, I think Omnidots is the ideal product on the market right now."

Martijn van Delft

Vibration Monitoring Expert at Allnamics

“We were watching the monitoring market for innovations when we encountered the Omnidots refreshing approach. It was immediately clear that this was a new, exciting take on the market and a chance to provide the UK market with a modern vibration monitoring solution, backed by a cloud-based monitoring and support portal."

Jenny Krailing

From EEMC Monitors

![]()

“With the same number of people, and in the same amount of time, we can now place three or four times as many monitoring devices as with the older systems.”

Tom Smits

Monitoring Expert at Quattro Expertise

Intuitive solution for the construction and infrastructure sector

Most of our clients use the SWARM Vibration monitor worldwide in construction and infrastructure. Thanks to its intuitive nature, you don't need to follow long training sessions to work with this device.

Do you want to prevent potential vibration damage to structures and nuisance for people outside of the construction scope? So far, our clients are successfully using the SWARM Vibration to measure vibrations at windmills, data centers, and heavy-traffic sites.

What you can expect from the SWARM Vibration

The SWARM Vibration in a nutshell

1 screw mounting & automatic alignment

Configurable alarm and alerts

Receive alarms per e-mail or SMS when the recorded measurements exceed relevant guidelines or your own preferences. Admins also receive important alerts about the status of their monitoring devices.

Export vibration monitoring data

You can download all monitoring data as CSV or Excel files, or retrieve the data using the Omnidots API.

MEMS technology

MEMS sensors improve your monitoring experience by saving time, money, and effort.

Wireless connection

The measurement data is automatically sent from the SWARM Vibration to the Honeycomb platform via 4G/LTE or WiFi.

Real-time visual data

Get instant insights from your project. Prevent structural damage and nuisance by stepping in when needed.

More details about the SWARM Vibration

Article numbers: SWARM V2.2b-G, SWARM V2.2c-G, SWARM V2.2cw-G

Complies with industry standards:

- DIN4150-2, DIN4150-3, DIN 45669-1, BS7385, BS6841, ISO2631, SBR-A 2010, SBR-A 2017, SBR-B, Circulaire du 23/07/1986, ISEE (USBM RI8507 & OSMRE) and SN640312a.

- The SWARM Vibration continuously sends the measurement data automatically to Honeycomb via 4G/LTE, WiFi, or PoE using an adapter.

- Mounting is very quick and easy.

- The SWARM Vibration is compact, lightweight, and IP65-rated.

- GPS timing: This allows you to pinpoint the exact time of an event and lets you easily compare the data with other sensors.

|

|

SWARM V2.2b |

SWARM V2.2c |

SWARM V2.2cw |

|

Applicable standards |

|

|

|

|

Range frequency |

0.5 - 250 Hz | 0.5 - 250 Hz | 0.5 - 250 Hz |

|

Range velocity |

±50 mm/s (±2 in/s) | ±50 mm/s (±2 in/s) | ±300.0 mm/s (±12 in/s) |

|

Noise (RMS) |

50 um/s at 250 Hz BW (2 mil/s) | 25 um/s at 250 Hz BW (1 mil/s) | 25 um/s at 250 Hz BW (1 mil/s) |

|

Resolution |

1 um/s (0.04 mil/s) | 0.5 um/s (0.02 mil/s) | 0.5 um/s (0.02 mil/s) |

SWARM Vibration technical specifications

Discover all accessories

See all the indispensable accessories for real-time vibration and dust monitoring.

Active in 42 countries

Omnidots is striving to be a worldwide provider of environmental monitoring solutions.

Measurements

Since 2018, our clients have conducted more than 32k measurements with our solution.

Happy Customers

95% happy customers in 2023.

Use case: Ground vibration monitoring in mine blasting

Nicolás Acuña Caro

SEMAM, Chile

For this project, SEMAM uses three SWARM Vibration devices with batteries to measure the ground vibrations at the copper mine site. "It is so useful for us that we can still do the measurements even when the SWARM Vibration cannot connect to any network while being in the desert. The SWARM Vibration keeps measuring and storing its data until it comes online. At the mining site, we make a quick measurement, go to the office, download the data and then analyze it. The Omnidots solution is really easy to use."

Discover how the SWARM Vibration can help your organization

Read our blog

Calibration Frequency: Geophone vs SWARM Vibration

INTERGEO 2024 in Stuttgart: Claim your Free Ticket & Connect with Omnidots

Exploring Vibration Standards: A Deep Dive into ISEE/USBM Guidelines for Structural Safety

Discover other products

SWARM Sound level meter

The new standard in sound level monitoring.

Cloud software | Honeycomb

Cloud-based SaaS platform

Accessories | SWARM Battery

Compact and handy SWARM battery